Print Q&A

Glossy film and fogging film are commonly used printing processing technologies, mainly used to improve the appearance and protective performance of printed matter.

Glossy film: This film has a smooth, shiny surface and feels similar to non-sticky tape. It gives the print a certain degree of water resistance, making the surface easy to clean. However, since it only covers the surface of the print and does not seal the edges, the sides are still exposed to moisture and are not completely waterproof. In addition, the gloss film can also enhance the durability of the printed matter and prevent it from tearing easily.

Matt film: This film has a soft surface, matte texture, delicate touch, and low reflective effect, giving the printed matter a low-key luxury feel. Similarly, although the fogging film improves the waterproof performance of the paper, its waterproof ability is limited because the edges are not sealed. The characteristics of the fog film make it difficult to tear and provide a unique visual and tactile feeling.

When choosing a waterproof sticker, you need to consider the environment in which the sticker will be used, such as whether it needs to be refrigerated or frequently exposed to water. For applications in the food or catering industry, it is recommended to use PVC synthetic stickers because the plastic material has good waterproof and low-temperature resistance and will not lose its stickiness due to freezing. In addition, if you have special requirements for the appearance, you can choose pearlescent stickers to add texture, or transparent stickers with white ink to highlight the logo. For an environmentally friendly option, PET synthetic paper is a good choice because it breaks down easily and has less impact on the environment. These stickers can be further processed through hot stamping or lamination to enhance the protection and sophistication of the printed surface.

By understanding the characteristics and applications of various printing materials, you can choose the most appropriate printing processing technology based on your specific needs to achieve both beautiful and practical results.

The lamination process is a process of covering the surface of printed matter with a layer of plastic film, which is mainly achieved by heating, pressurizing and cooling. This technology is mainly used to increase the beauty, durability and protection of printed matter.

Principle: Combine plastic film and adhesive on the surface of the printed matter, and make it tightly bonded to the paper through the processing process.

Purpose and function:

Enhance appearance: Make prints more vivid and shiny.

IMPROVED DURABILITY: Increases tensile strength, water resistance, and prevents scratches and scuffs.

Protect printed matter: waterproof, anti-fouling, extending service life.

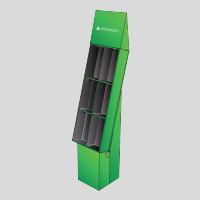

Scope of application: Widely used in digital product packaging, advertising prints, exquisite album covers, books, handbags, etc., especially those printing products that require enhanced appearance and durability.

Although the coating process offers many advantages, there are also environmental concerns. For example, the chemicals used in the processing may cause a burden on the environment, and the coated products are difficult to recycle. Therefore, when choosing to use the coating process, a reasonable choice should be made based on specific needs and environmental protection standards.

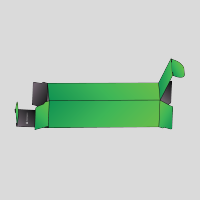

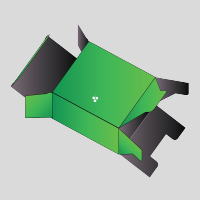

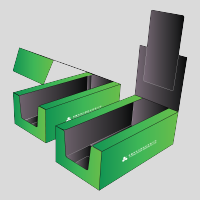

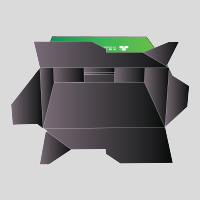

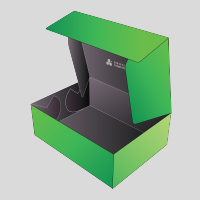

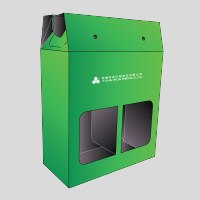

The structure of the corrugated color box is mainly to enhance the sturdiness, weight resistance and pressure resistance of the packaging box. This structure usually includes a combination of face paper and two layers of corrugated paper. Tissue paper is mainly used for printing and can be divided into two categories: gray copper paper made from recycled pulp and white card made from original pulp. The printing side of gray copper paper is white and the back is gray; while the printing side of white card is white. The choice of tissue not only affects the appearance, but also affects the overall cost, because the thickness of tissue is directly related to the specifications of corrugated paper.

Corrugated paper is mainly used for support and protection. Common types include B wave (3mm), E wave (2mm), and F wave (1mm). The thicker the corrugated paper, the stronger its pressure resistance and the better it can maintain the integrity of the box shape. Commonly used backing paper colors include yellow, white and black, and other colors can be customized according to needs. With the appropriate combination of tissue paper and corrugated paper, you can create beautiful and sturdy colorful corrugated boxes.

Glazing is a printing processing technology mainly used to increase the surface gloss and texture of printed matter. Common glazing methods include using plastic film, varnish or other materials for pressure treatment. This not only beautifies the paper, but also increases the overall value of the printed matter. Water-based varnish and PP film are two commonly used glazing methods. Water-based varnish is affordable but has weak protection, while PP film provides better protection and increased durability.

PP film and PVC glazing are both common methods for protecting printed matter, but they have different characteristics and uses. PP film is suitable for increasing brightness and chroma. It is divided into bright film and fog film, and it can effectively prevent water splashing and scratching. In contrast, PVC glazing is more suitable for products that require high durability, such as backing boards and hang tags, due to its hard texture and waterproof properties.

PVA glazing uses a synthetic resin coating, which is waterproof and beautiful, but you need to pay attention to the drying state of the ink to avoid falling off. UV varnish is cured by ultraviolet light to provide wear-resistant, anti-fouling and smooth properties, and is especially suitable for prints that require high-quality visual effects. Both can improve the appearance and texture of printed matter, but the most appropriate processing method should be selected based on specific needs.

UV glazing (local) is mainly used to highlight specific areas and increase the visual effect of patterns or text. This method is suitable for advertising materials and special packaging, and can make details more eye-catching. Hot stamping is a luxurious printing and decoration technology that uses metal foil to increase the gorgeousness of printed matter. It is often used in business cards, high-end packaging, etc. to enhance brand image and product quality.

ISO paper size is a set of international standards developed by the International Standards Organization and is widely used in books, magazines, commercial advertising and artwork printing. Commonly used in Taiwan are the chrysanthemum version and the 46 version. The chrysanthemum version is equivalent to the A series, and the 46 version is equivalent to the B series.

Grams of paper represent the weight of paper per square meter. For example, 128g/m² glossy paper means a weight of 128 grams per square meter.

Paper thickness is usually expressed in "line numbers", with one line equal to 0.01 mm. Lines are used instead of millimeters because the paper is thinner and using lines avoids confusion caused by decimal points.

Packaging boxes are made of various paper materials, and each material has its own unique characteristics and uses, including the following: Clay Coated Paper: This kind of paper is white on one side and gray on the other. It is usually used for bottom of the box for added structural strength. White copper paper (White Board): It has a printable white surface and a gray back, suitable for packaging boxes with beautiful patterns or text. One Side Coated Paper: One side can be printed, and the paper is hard. It is suitable for making exquisite high-end gift boxes or food boxes. Corrugated Board: With a single or double layer structure, the wavy shape provides additional protection and strength, and is used to make shipping boxes that require strong strength. Kraft Paper: Rough texture, dark color, and leather-like touch. It is often used to make handmade gift boxes or handbags with special texture. Environmentally friendly Red Ox cardboard: Contains 70% environmentally friendly pulp, suitable for packaging that requires environmentally friendly materials, although the printing color expression is weak. Gold/Silver Foil Paper: Gold and silver foil is attached to the surface, giving the packaging a luxurious feel. It is often used in high-end product packaging, such as gift boxes and food boxes.

When choosing printing paper, you should consider the characteristics of the paper and the style of the publication, and seek advice from the printer or paper dealer. Special printing techniques such as using metallic colors, embossing or rolling should also be considered.

There are various types of printed stickers, such as glossy stickers, written stickers, transparent stickers, etc. Each sticker has its own unique characteristics and application occasions. For example, anti-counterfeiting fragile stickers are suitable for tamper-evident product packaging.

Whether the sticker is waterproof depends on the material. Some stickers such as glossy white PE stickers have a basic waterproof effect, but if the base material is not waterproof, it cannot be completely waterproof.

Special color inks usually refer to inks that are not CMYK standard colors, such as colors in the Pantone color system. They are used to achieve special color effects in printing.

UV ink can dry quickly after being exposed to ultraviolet light and is suitable for a variety of materials. In comparison, traditional inks require longer drying times and are typically used for paper printing.

Ink selection should be based on paper, printing needs and environmental factors. For example, outdoor posters should use UV-resistant inks to prevent fading, and food packaging should use oil-resistant, lead-free inks.

Bleed is an important concept in print design, especially in poster, magazine or packaging design. The bleed line refers to an additional area on the edge of the design draft, usually 2 to 5 mm, used to prevent mechanical errors during the cutting process from affecting the appearance of the finished product. If the design involves bag making, these bleeds are used in the heat sealing and cutting steps to ensure that design elements are not accidentally cut off.

Color differences in printed matter usually result from differences in color representation between the screen and the print. Screen display uses RGB mode, while printing mostly uses CMYK mode. The color principles of the two are different. To avoid chromatic aberration, it is recommended to perform screen color calibration and convert to CMYK color mode when designing. Especially when using image filters, you need to pay more attention to adjustments to meet printing requirements.

Traditional hot stamping transfers gold foil to paper through heat pressing, which is suitable for high-end packaging or books. Three-dimensional UV foil stamping prints UV glue first and then foil stamping, creating a more significant three-dimensional effect and level of detail, which is suitable for prints that require special decorative effects. Three-dimensional UV hot stamping has low cost and is suitable for diverse design needs.

Lithography: Suitable for high-quality multi-color prints such as books and magazines. Gravure printing: suitable for mass printing that requires fine levels of detail, such as color magazines. Screen printing: suitable for printing on special materials or requiring special effects, such as glass or metal. Letterpress printing: Ideal for prints that require a strong impression or a heavy feel, such as business forms or gift cards.

Combined printing is a combination of multiple customers' works being printed on the same layout. It is low-cost but difficult to control color. It is suitable for printing in small quantities and with low color requirements. Independent printing means that each customer's work is printed independently, with good color quality, and is suitable for high-end printing or orders with strict color requirements.

All kinds of post-processing, such as partial gloss, white ink, hot stamping, embossing, rolling, etc., require special layers or marks to be set when the manuscript is completed. For example, local UV, white ink or hot stamping needs to be drawn on a dedicated layer of K100, while rolling requires the die line to be drawn independently on a layer to ensure processing accuracy and quality. Through the above reorganization and writing, you can understand common printing problems and solutions more clearly, so as to make more appropriate decisions when choosing and using printing services.

Packaging boxes are mainly used to protect, display and promote products, and their materials include cardboard, plastic, etc. The hardcover box is a high-quality packaging box used for high-end products. It is known for its sturdy structure and exquisite appearance. It is usually made of high-hardness thick cardboard with exquisite surface decoration.

When designing packaging boxes, you need to consider aesthetics, brand communication, environmental protection and user experience. The design should be in line with the product positioning and target market, while selecting suitable materials and creative designs to attract consumers.

Hardcover boxes are usually used to package higher-end goods, and their materials and production processes are more sophisticated than ordinary packaging boxes. Features include unique opening and closing methods, special printing techniques and decorative details such as hot stamping, ribbons and magnetic closures.

Before producing the hardcover box, prototypes and samples need to be made to ensure that the design and functionality meet the requirements. Quality control is a necessary step to ensure product quality. In addition, the cost and production time of hardcover boxes are usually higher and require reasonable planning.

Market trends show that more and more brands and consumers are paying attention to environmental protection and choosing sustainable materials. Technology integration, such as AR technology, is also used to enhance the interactivity of packaging. In addition, the increasing demand for personalization and customization requires packaging design to be more flexible and personalized.

Welcome to consult and negotiate, we are at your service at any time!

The first choice for market cabinets and small and medium-sized enterprises, high-quality carton printing, affordable prices, and one-stop high-quality service.

Contact us immediately and our sales specialist will serve you one-on-one!